As CNCRay, we produce professionally with the principle of "perfection" without compromising the quality standard, and we reflect the perfection in every product to all details.

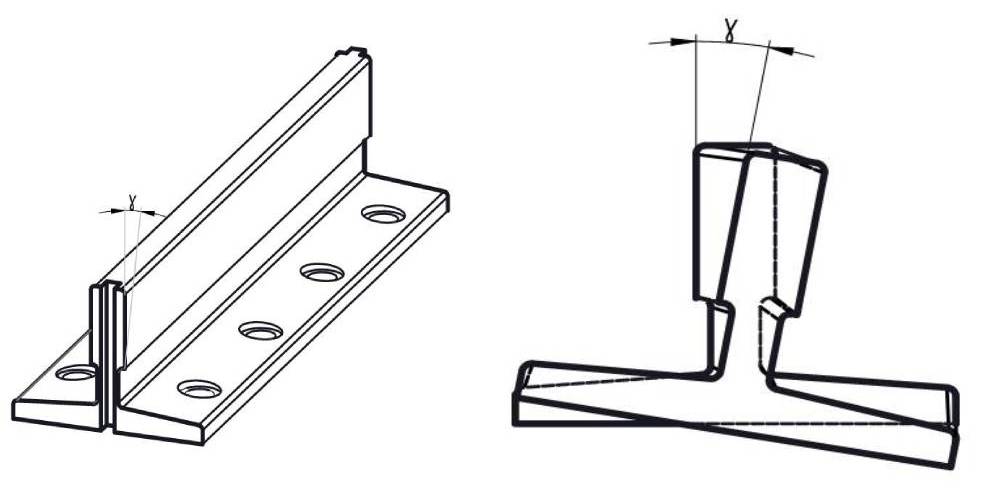

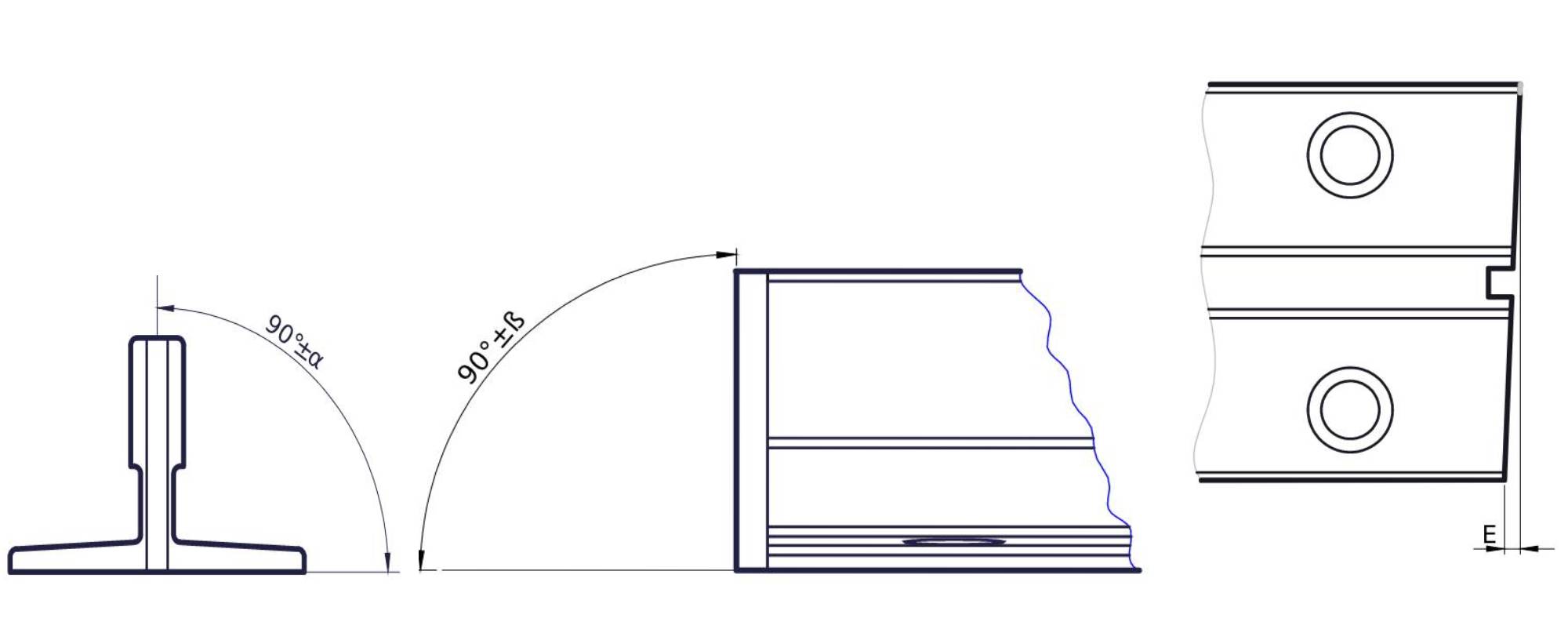

Elevator guide rails are manufactured according to the international standard ISO 7465 Passenger lifts and service lifts- Guide rails for lift cars and counterweights- T type. Guide rails may be cold drawn or machined. The manufacturing process for each type of guide rail is indicated by the symbol / A for “cold drawn”, the symbol/ B for “machined”, and the symbol/ BE for “machined high quality.”

Guide rails complying with the requirements of ISO 7465 shall be designated as follows:

EXAMPLES:

ISO 7465-T70/A

ISO 7465-T89/BISO 7565-T90/BE

*In our brand markings “TS” letters stand for “Turkish Standards” which are in total compliance with the ISO standards.

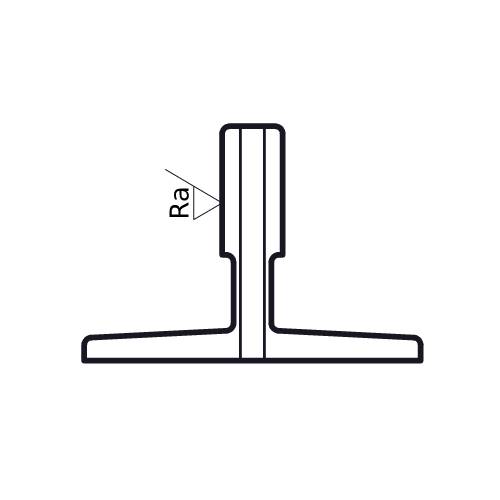

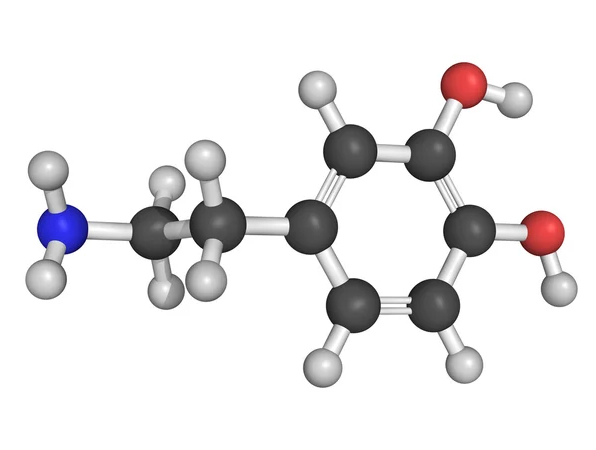

Surface roughness is a measurement for the structure of the surface. It is calculated as a vertical deviation of the actual surface from its ideal shape, caused by machining or by chemical or physical processing in production. If these deviations are high, the surface is rough. If the value is low, the surface is smooth. Roughness measuring instruments state the roughness in Ra values.

One of the main differences between cold drawn and machined rails is the roughness of the blade. To provide comfort and velocity, the surface of the blade should be smooth and flawless. The blade roughness also has implications for the break distance of the safety grip. Whereas the surface roughness of a guide rail may be 1,6 µm ≤ Ra ≤ 6,3 µm longitudinal and transverse for (A) cold drawn rails, the same parameter for machined guide rails should be Ra ≤ 1,6 µm longitudinally and 0,8 µm ≤ Ra ≤ 3,2 µm transversely.

| Surface Roughness | Cold Drawn(A) | Machined(B) | High Quality Machined(BE) |

| Longitudinal | 1,6 µm ≤ Ra ≤ 6,3 µm | Ra ≤ 1,6 µm | Ra ≤ 1,6 µm |

| Transverse | 0,8 µm ≤ Ra ≤ 3,2 µm | 0,8 µm ≤ Ra ≤ 3,2 µm |

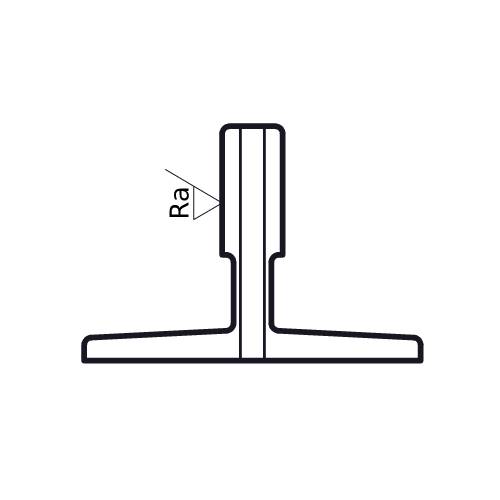

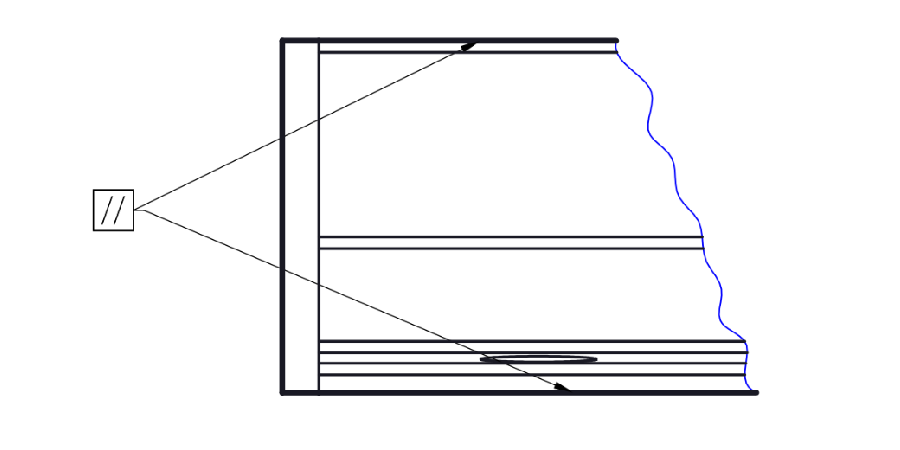

Straightness, is a tolerance used to control the form of a line on the blade surface. A bending point on the guide rail may exert a reaction force on the guide shoe which can cause the cabin ride erratically. The vibration reduces the ride comfort and velocity.

| Straightness | Machined(B) | High Qualty Machined(BE) |

| B/A | 0,0010 | 0,0004 |

| B/5 m | 1 mm | 0,5 mm |

γ max = 1mm/5m

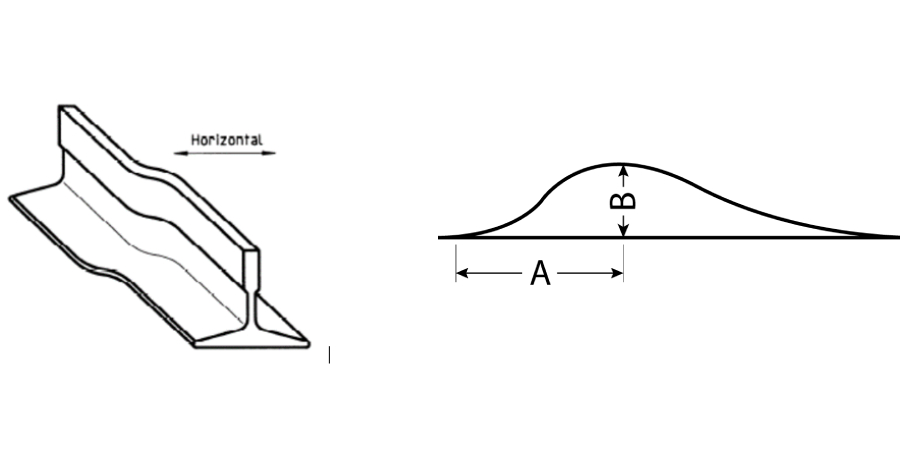

It means the parallelism of bottom foot surface and top surface of the blade, ISO standard specification is ≤0.05 mm. The parallelism impacts the joint precision of guide rails and enhances smoothness and comfort of elevator.

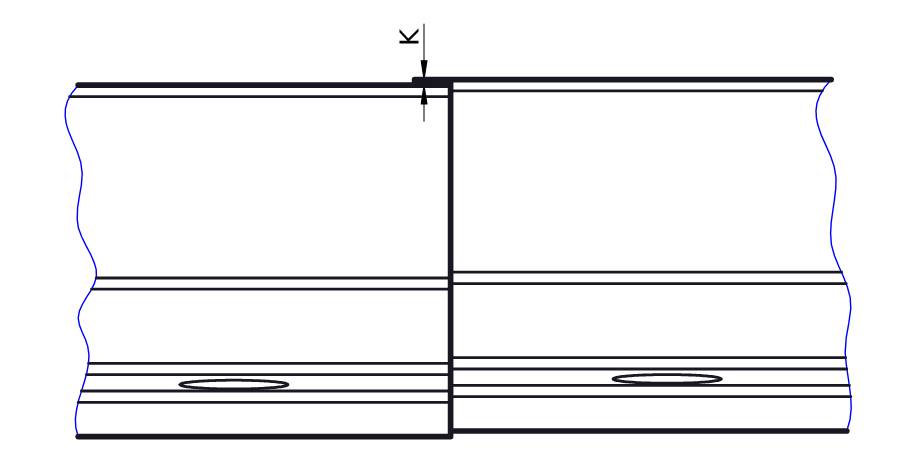

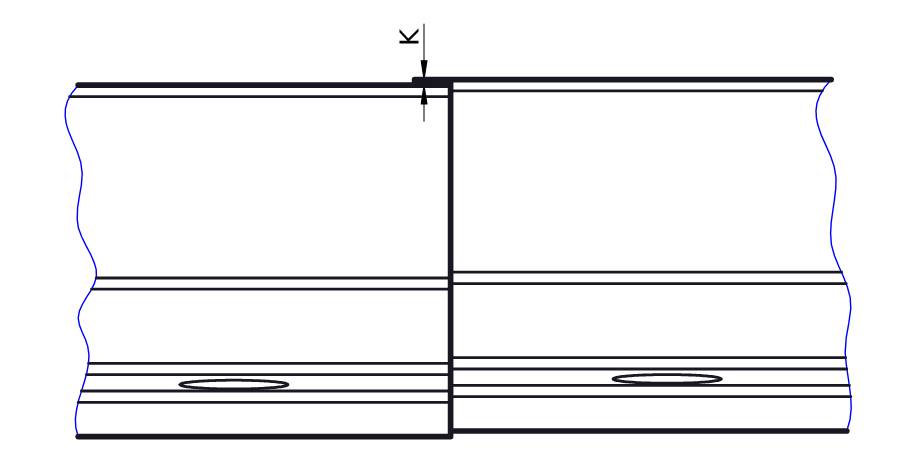

The precision of the guide height is vital for a perfect joint and providing a linear surface. Smooth rail surfaces and flawless joints ensures no burring and rail jumps. This brings implications on comfort, noise, vibration and maintenance costs. According to ISO 7465 standards, the height of the guide rail should have ≤0,1 mm tolerance in B type machined guide rails, and ≤0,05 mm tolerance in BE type high quality machined guide rails.

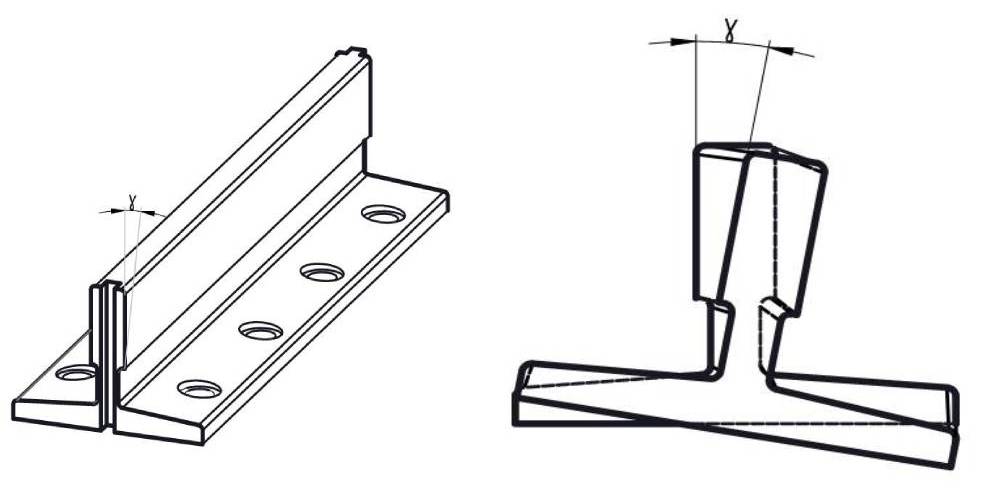

Perpendicularity tolerance is considered for the angular difference between the blade and the foot plane; the key and the foot plane; and the perpendicularity of machined surfaces for the fishplates. The perpendicularity impacts the guide rail joint accuracy, therefore provides smoothness and comfort. ISO tolerance specification is 0,1mm for B type machined guide rails and 0,05 mm for BE type high quality machined guide rails.

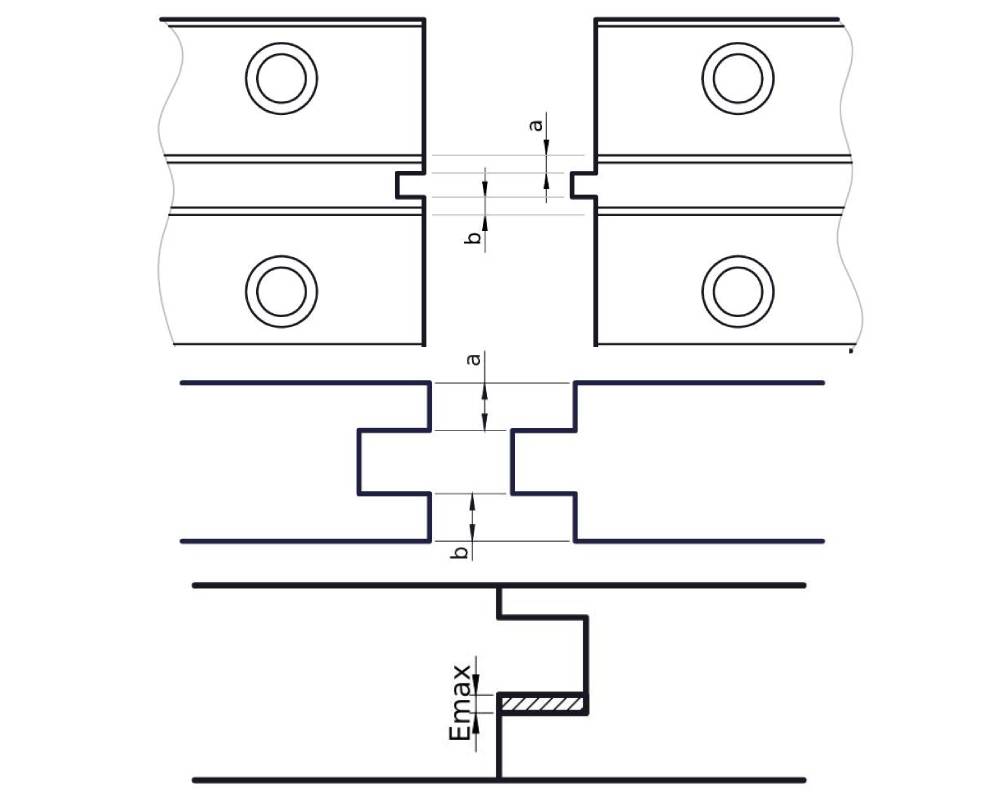

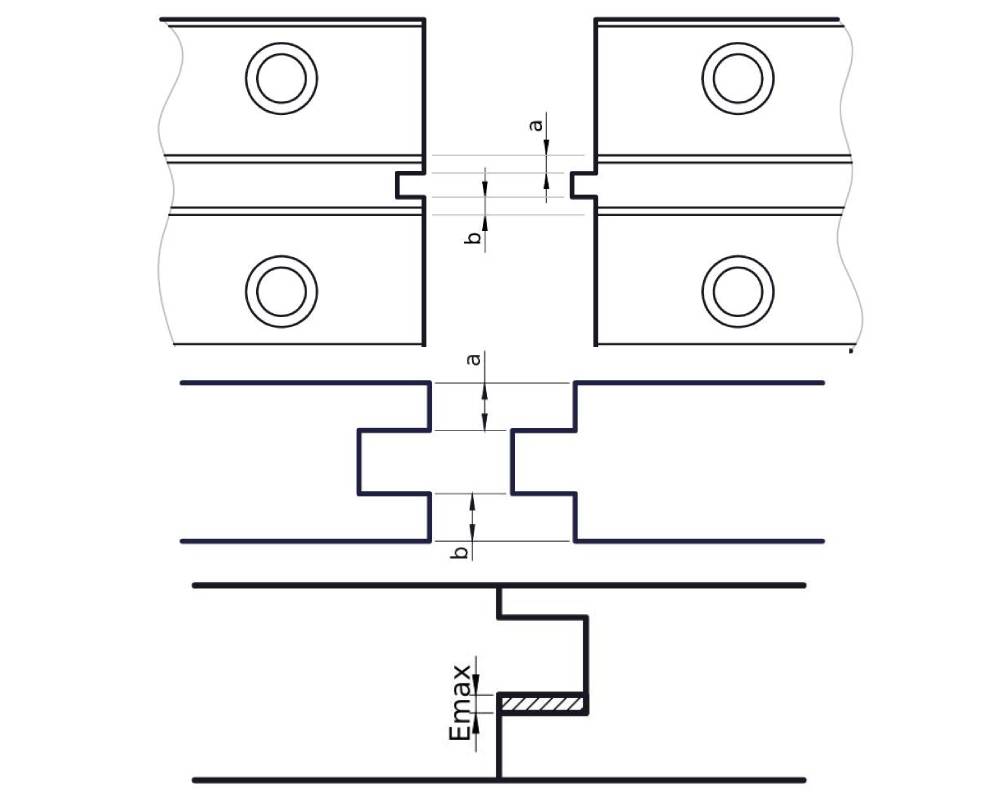

It means the centering of the key and keyway; ISO 7465 standard specification is ≤0.1mm for machined guide rails, and ≤0.05 mm for high precision elevator guide rails. Maximum clearance between the key and keyway has to be less than 0,12 mm for machined guide rails and 0,06 mm for high quality guide rails. Centering brings significant impact to joint precision by maintaining stable movement and comfort for the cabin.

| Centering Tolerance | Machined(B) | High Qualty Machined(BE) |

| a-b | ≤ 0,1 mm | ≤ 0,05 mm |

| Emax | ≤ 0,12 mm | ≤ 0,06 mm |

According to ISO 7465 standard, the tensile strength of the steel has to be between 370 N/mm² and 520 N/mm². Therefore, E 275 B coded steel is used for machined guide rail production. The tensile strength of guide rail ensures the safety grip having sufficient support during the brake mechanism taking place.

The ISO standard states the linear density for a finished guide rail in “kg/meter” units.

For example, the linear density of a T89/B machined guide rail is 12,3 kg/m. So, a 5-meter long standard bar should be not less than 61,5 kilograms. An elevator guide rail which weighs less than the criterion cannot be expected to support the tensile strength in case of emergency.

E 275 B Steel is used for manufacture.

(C): 0,14%—0,20%;

(Si): 0,19 %;

(Mn): 0,58-0,69 % ;

(P): 0,010-0,012 %;

(S): 0,010-0,021 %.

Carbon content is the most important content in steel. Increase carbon content in steel, the breaking point and tensile strength will be increased as well but the elongation and resistance to impact will be reduced.

Silicon acts as a reducing and deoxidizing agent.

Manganese acts as a deoxidizing and desulfurizing agent, it improves toughness and strength properties of steel.

Phosphorus and Sulphur are toxic agents in the steel, they both reduce elongation and toughness property of steel.

The hardness of guide rail ensures the safety grip to gain sufficient friction.

Dirty, oxidized or otherwise unfinished material is undesirable for many reasons. Material that is covered in mill scale, dirt, and other debris is generally aesthetically displeasing. Oxidized material may present problems with fabrication processes such as welding or machining. Applying a coating to unclean materials can cause a lack of adhesion. Sharp burrs and edges can cause lacerations. For these reasons, materials need to be cleaned prior to many different types of manufacturing processes such as coating and machining.

Shot blasting is a mechanical full 360° cleaning process that uses spheres of material to remove oxides and other debris from the surface of another material.

The foot of the elevator guide rails are coated with paint against oxidation and rust.

| Anti-Rust Prevention* | |||

| Type | Thickness | Months / Outdoors |

Months / Indoors |

| CORES DF-5 (Oil) | 2-10 µ | 6 | 12 |

| CORES DF-10(Oil) | 4-20 µ | 9 | 12 |

| CORES 36 (Wax) | 40-50 µ | 6-24 | 12-36 |

| *Data could change according to environmental humidity and salinity. | |||

We have special packing solutions to fulfill customer logistic needs and guide rail protection. Special sea packing is also available. The protective caps that we supply guarantee preservation of the quality (keys-keyways) even at the installation site. The packages are neatly closed airtight. The desiccant silica gels prevent corrosion by reducing the amount of moisture present in the packet.

The packages are easy for transportation and dismounting.

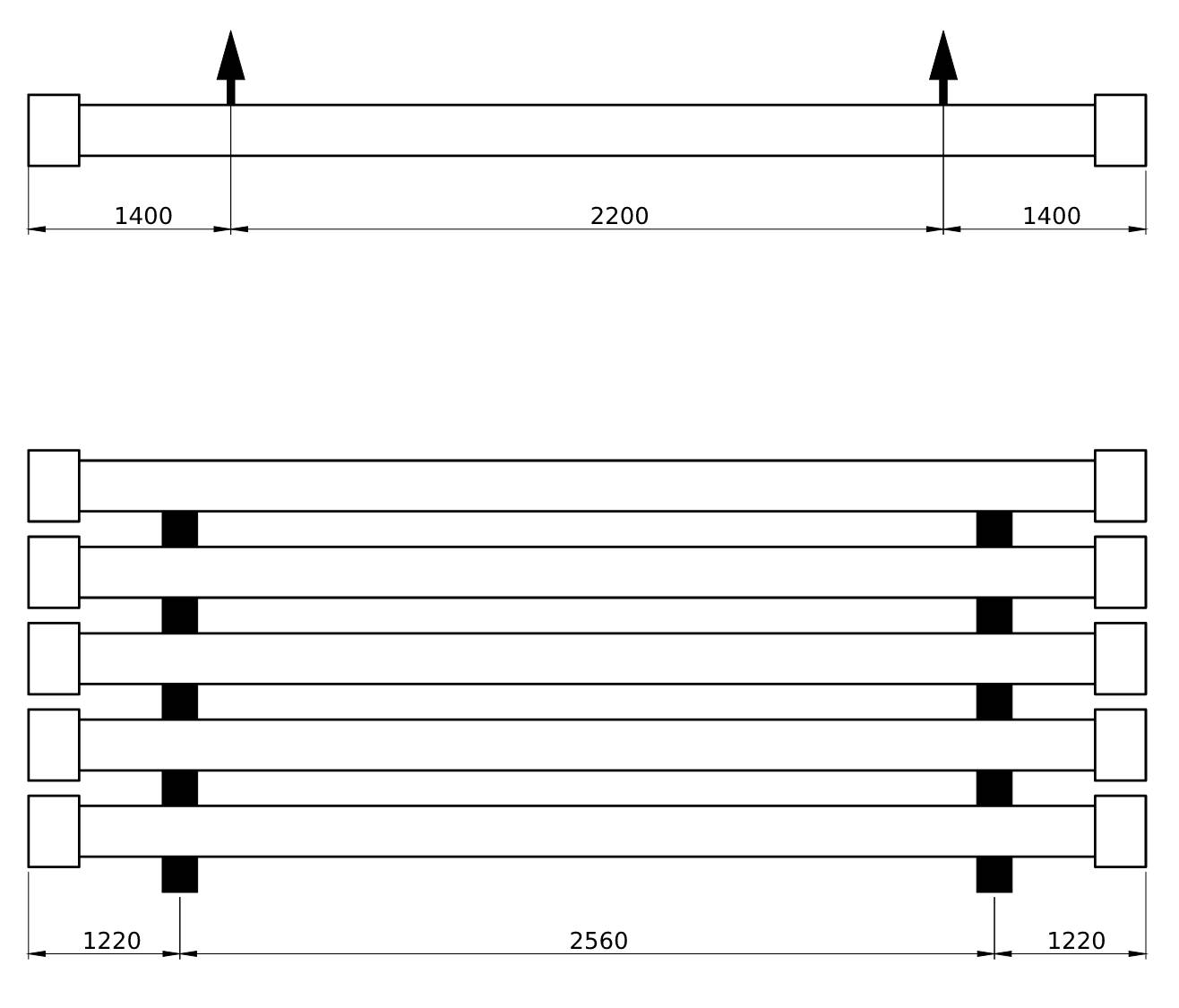

Packages must be lifted with forklifts or a crane with two slings – one sling placed at each end of the bundle. The minimum distance between the two slings must be 220 cm, which means the lifting points will be 140 cm from each end. We advice to handle one package at a time.

Packages must be stored horizontally on wooden blocking, placed for each level of package and at the same distance from the ends. Appropriate storage prevents any permanent deformation and loss of linearity properties of the guide rails.

Packages should be protected from direct sunlight and precipitation. Packages must be kept closed and stored under a roof. The storage tempature should be between 5 ℃-40℃.

The rails must be carried precariously to prevent from plunging and crushing into other objects. The protective caps must be removed just before installation.

CNCRAY reserves the right to change the written specifications without notice.